Air Handling Units

From medium-sized heat recovery to large-scale air handling units, IDVRS ensures optimal climate conditions for buildings of all sizes and applications

From medium-sized heat recovery to large-scale air handling units, IDVRS ensures optimal climate conditions for buildings of all sizes and applications

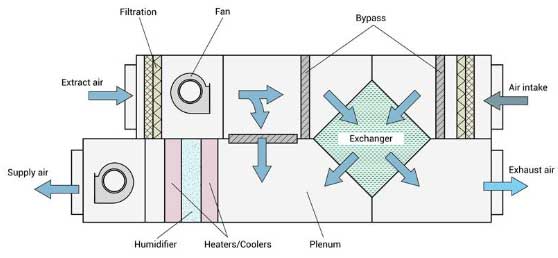

An air handling unit, commonly called an AHU, is the composition of elements mounted in large, accessible box-shaped units called modules, which house the appropriate ventilation requirements for purifying, air-conditioning or renewing the indoor air in a building or premises.

They are usually installed on the roof of buildings and, through ducts, the air is circulated to reach each of the rooms in the building in question.

In addition to managing the proper ventilation of the interior with outside air, the AHU performs other functions:

For its part, the places for which the AHU is intended are those in which the flow of people is very large and accumulates many people at the same time and whose natural ventilation is limited: hotel dining rooms, function rooms, restaurants, convention halls... It is also a suitable option for those spaces with very high hygiene requirements: laboratories, clean rooms or operating theaters, among others. An AHU can also be used to ventilate places where air conditioning is provided by radiators or underfloor heating, for example.

The ultimate aim of an air handling unit is energy efficiency and this is mandatory since 2016 by the European Ecodesign Regulation 1235/2014.

By having heat recovery units, the AHU reduces the use of energy required in air conditioning, as in the exchanger, the indoor and outdoor air is mixed, so that when the air reaches the coil the temperature contrast is lower, therefore, the climatic contribution is also lower and energy consumption is also reduced.

Likewise, the variable regulation of the equipment means that the fans can work according to the flow rate needs, reducing their consumption.

Fresh Air Handling Unit (FAHU) is an excellent solution for regulating and circulating fresh air as part of an HVAC system and it ensures a constant flow of fresh clean air and a very well-conditioned environment.Capable of withstanding external static pressure of up to 1000pa, Finpower SK 50T Series FAHUs are efficient enough to endure air volume from 1700 CMH to 60000 CMH.